Discussed in the previous article was how technology has greatly improved for robot welding systems. State-of-the -art technology for robot welding and sustained focus on usability is converging to help the high mix, low volume manufacturing for New Zealand.

The immediate question typically asked from end users is how they go about using robot welding systems and skills they will require. As mentioned in our prior article is how technology and usability has significantly improved since the early applications days. This article will expand on the user skillsets and programming tools for modern robot welding.

Your Skillset for Robot Welding Systems

Beyond the well-known benefit of reducing labour, the other key aspect is helping scale operations. Robot welding offers the opportunity to maximise the outcome from your existing welding expertise. Moreso than just labour saving, this is becoming particularly important as qualified welders are becoming a scarce resource.

Already having operators with experience of robot welding would be best prior before install, but its not critical. One secret it is not robot programmers but experienced welders who make the best programmers of robot welding cells. It takes years to gain the knowledge and experience to become expert welder; and required robot skills for welding can be learnt in weeks.

The complicated robot element is during the install and handled by your integrator. By the time the robot welding system is configured and setup for production, the robot skills are on the very simple end of the spectrum. Properly trained and support by your integrator, and some homework, within a few days for getting feet wet and within several weeks becoming self-sufficient.

Were one factor often not considered for manufactures is effectively productising and scaling the use of your welding expertise. Whereas manual welding requires expert hands-on involvement for each part; pair your welder with a robot and their expertise can them be applied to hundreds or thousands of parts from the initial effort

The difference between a 5 year experience and 10+ year experienced welder is not motor skills but the knowledge how to get the best quality, speed and solutions to problems. Robotic welding allows them to get away from dirty and monotonous aspects and into professional role based around this knowledge. There will always those who prefer the hands-on work but having access and learning the robot element offers greater opportunity for experienced welders.

Give the welder a robot and not only does it remove the need to spend their day in the dirty, hot, and hazardous environment; but to have that time being mentally engaged and challenged. The welder then spends their time deciding how each part should be made, different techniques, current settings, speed, stick out etc.

In the next leap for manufacturers that concentrated knowledge effort with the consistent quality control helps continuous improvement and lean manufacturing. With a consistent quality of parts your welding operations and production engineering group can then work towards gradual improvements whether that is higher throughput, less warpage, less materials, better seam quality etc. This is both beneficial to your business overall bottom line and the daily role of your welders meaning you hang on to them longer.

Programming Tools for Robot Welding Systems

The original means of programming welding robots, and in general all industrial robots involves physically driving the robot to each location and “teaching” that point, and thus the name given to a robot’s handheld control is a “teach pendant.” This was and is still regularly used in many applications and is valid approach, you are after all hands-on teaching the robot to the real part.

There are two main downsides to this approach for welding applications.

- Firstly, this is very tedious and takes the programmer a very long time to program each part. I have met robot programmers who have spent a week teaching a single part for heavy industries.

- The second, and far more costly, is welding production is halted during part teaching. The general rule of thumb is a robot has the rate of three manual welders, if not more when considering external axes repositing parts.

All in all, each hour of robot stoppage runs well into the order of hundreds of dollars of lost production plus the time of your robot programmer.

This manual approach is for why for years robotic welding was restricted to large mass-producing markets such as automotive. The overhead in capital cost, and overhead per job has made robotic welding into our smaller manufacturer a long time coming.

Offline Robotic Programming

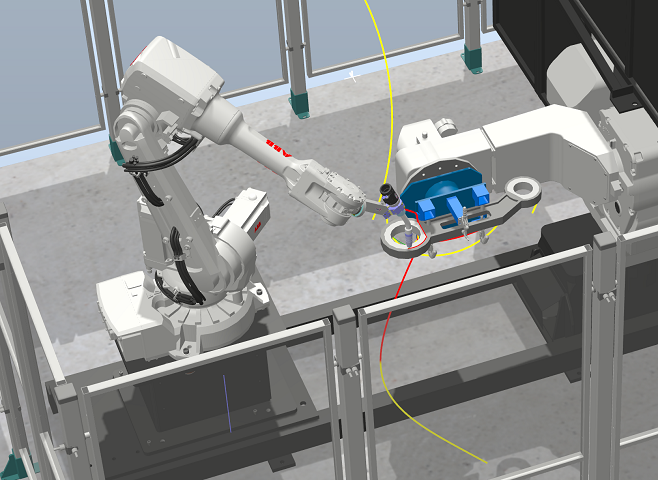

Offline programming can be achieved by a range software and simulation packages that allow a robot to programmed on a computer and allow the physical unit to remain in production. These packages offer simplified programming and significantly reduce overheads for each new part.

ABB Arc Welding Package and Tools, RoboGuide

As CAM packages have greatly improved the efficiency of translating CAD to CNC programs; offline robotic programming has aided the development of robot programs.

In addition to the programmer no longer having to climb all around a robot cell, there are number of productivity enhancements. These enhancements allow the programmer to focus on the welding application rather than minute details of robot motion and detailed programming commands

Welding robot’s have been around since the 1980s, so while there may be the odd occasion a programmer needs to add something specific, most of a programmer’s time can now actually be spent picking seams, the correct torch orientation, stick out etc.

This also leads to reinforce the earlier point from Part 1, the best robotic welding programmers, are WELDERS!

Compared to traditional methods, offline programming, and especially when including Add-On welding packages, can easily reducing programming time 50% and much more for large and complicated parts. The big benefit, however, is the robot remains in production earning money while the new part is being programmed. Extrapolate out these differences even conservatively, and the part overhead costs have been reduced by 80%, likely over 90%.

Offline Robotic Programming Software

Offline robotic programming software can be split into two “types” of software; visualisers, and simulators.

- Simulation programs are from the robot manufacturers themselves, and tend to be more functional software tool that also have several background robotic and general production aids.

- Visualisation programs tend to be third party programs that are generic across various robot manufacturers and various stages of a systems total lifecycle.

The true simulation environment would seem the obvious choice except most robot manufacturers really only care about selling robot, and provide a very poor-quality solution, and thus the rise of the third-party solutions. The third-party solutions tend to heavily market towards usability, aesthetics, and “program” commonality between multiple robot brands.

The other key use for third party components, is more towards engineering companies, integrators as sales/concepting environments. These programs are great for putting early detail concepts together, considering overall product flow in large systems.

There is creditability and also hyperbole aspects to the third party marketing, so you need to consider your application.

Selecting Robotic Programming Software

Consider the following points for selecting a 3rd party offering over the native solution by from the manufacture of your robotic welding systems.

- Have multiple robot manufacturers.

- Have complicated parts to program

- Have robots other than ABB/FANUC

- Happy to accept less than ideal results.

The first two elements are tied into what a third party robotic programming solution may offer. The third party solutions from the get go are focused on the user; whereas all the manufacturer solutions were, originally at least, an technical tool to operate the robot.

Using across multiple manufacturers is commonly pushed by 3rd party offerings; but it really depends upon the scale of your operations, and how many and of which robot manufactures. In reality you will still need to learn each manufacturers system and terminology. The first thing you’ll do with a ABB or Kuka robot for example is install ABB’s Robot Studio or Kuka’s Works Visual.

The third party solutions will be more intuitive to an untrained person, but the reality is whoever operates and/or programs a robot welding cell will need at least some training; and this no different to any professional tool. There is certainly some benefit long term to the easier use, but remember there are more factors to consider than simply selecting edges in a 3D model. In most cases you’ll certainly prototype a part program faster with third party option, but by the time program has been optimised the options will start to even up.

- Contract manufactures will offer the opportunity to achieve the most gains from a suitable 3rd party solution; these being one-off part runs that put a premium on minimising initial setup and less on complete refinement.

- Internal manufacturers should strongly consider the native solutions for extra refinement options and long-term continuous improvement and product updates over a number of years.

ABB and FANUC have been singled out because both manufactures “get it” and provide good quality tools and documentation, other manufacturers can be diabolical. The equipment from ABB and FANUC is top notch; but our preference for these brands is because of the operational factors over a systems lifetime. Not only are these the sole manufacturers with factory support in NZ, the tools and documentation are what you care about once your system becomes a reality.

Some of the very high-end third-party options do let you develop a “program” a bit faster than ABB Robot Studio or FANUC Roboguide; but there is more to developing a program than just the motion of the welding torch. These offer tighter integration to the overall robot welding system, production tools, and less room for human error. In both ABB and FANUC’s cases both provide special welding software packages that are both very reasonable to use.

Note of Caution

The third-party solutions could be a great addition to your operation, but the major drawback you really need to be aware of, but you’ll never see in the marketing material or controlled demonstrations; real life accuracy.

You need to carefully consider what that risk could mean because crashing robots is an expensive mistake.

When using third-party tools, Before operating on the real robot I have always verified operation first with the native solution; and the native solution is the program used during commissioning. The way to think about this, third party visualisers will show what it should do, the manufacturer’s simulators will show you what the robot will do. (within reason)

The virtual robot(s) in ABB Robot Studio or FANUC Robot-guide use the same internal code as the physical robot and the simulation is an actual representation of what the real robot will do. (Not all manufacturers do this) In general, third party visualisers will program the torch positions adequately; but be questionable when detailing the full robot arm and exact path behaviour between weld seams. Experience using some of the larger well-known third-party tools has shown noticeable deviations with more complicated or optimised motion.

There is a certain amount of black magic in the brains of industrial robots. There are decades of work covering the complicated mathematics, practical approximations, and thousands of configuration settings. In one complicated project featuring multiple large 300kg payload robots with 50+ crossing locations with inter-robot speed of 80 km/h; it was only possible using ABB Robot Studio.

Comments are closed