Machine Vision Systems

Edge Robotics and Automation has a background in advanced machine vision with over a decade of developing world leading systems and history of industry focused PhD programs.

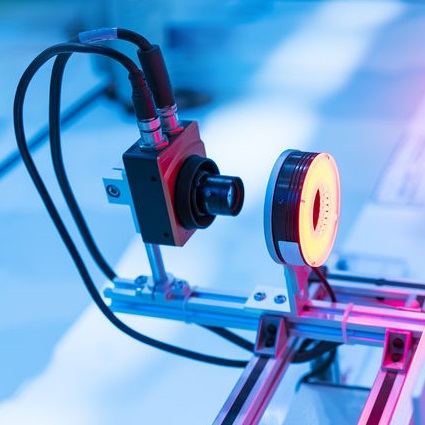

Smart Camera Devices & Systems

Smart camera devices offer a modular standalone machine vision package that is simple to use and easy to integrate for many standard factory applications.

These are standard off the shelf products or occasionally preconfigured multi-component vision systems from leading brands such as Cognex and Teledyne-Dalsa. Various products exists offering greyscale, colour and 3D technologies, with various resolutions and optical configurations.

Edge Robotics & Automation can further apply some advanced imaging techniques with smart devices to maximize the performance.

expert pC Based Vision Systems

Smart camera devices are ideal when they do offer a solution, however, these products are directed towards the “mass market” of industrial machine vision. When your vision needs go beyond the ordinary, PC based systems are often your best option.

PC based vision systems allow a fully customisable solution by allowing expert selection of much wider range of components, layout configuration, and powerful software.

Customisable vision systems can offer all the advanced imaging techniques and the opportunity to mix ‘n’ match components from world leading technology manufactures.

Machine Learning & AI

Machine Learning and AI approaches allow entirely new applications to be solved with machine vision systems.

Beyond all the recent hype, machine learning has quietly been in the background of Australia and NZ primary industries for over a decade.

Classical software code is in essence a rigid mathematical equation and this often struggles with our natural highly variable products and processes. In our primary industries machine learning is particularly helpful by giving machines a means to subjectively measure and control process similar or even beyond an expert human operator.

Edge Robotics & Automation has experience commercially applying machine learning techniques to a number of different challenges.

Advanced Imaging

Edge Robotics and Automation has experience with absolute bleeding edge imaging technology. This allows machine vision to go far beyond the vision perception of a human operator, and offers solutions to many challenges often thought entirely random.

The techniques are often found in expert PC based systems however some can be applied to smart devices to maximizing their full potential.

Near Infrared Imaging (NIR)

In the simple case NIR imaging can solve some of the nuccenises of conventional greyscale and colour machine vision systems. Beyond the ordinary imaging techniques, NIR is the introductory step of an entirely new sense of vision capability. When expertly harnessed NIR can make invisible objects appear in black & white clarity to imaging systems.

UV Fluorescence Spectroscopy

UV Fluorescence Spectroscopy is an extension of hyperspectral principles by instead using UV lighting to detect various forms of illuminous materials and organic compounds. Various imaging systems can be used from low cost mono/colour cameras to full hyperspectral cameras.

Polarimetry Imaging

Polarimetry imaging offers the advantage of precisely inspecting typically invisible defects or irregularities in transparent material, or inspecting surface texture and micro defects. The technique can be applied in examples such as measuring internal stress in glass, verifying seal quality in transparent packaging, microscopic particle size analysis and surface texture/finish on injected moulded parts.

Multi/Hyperspectral Imaging

Long been the domain of scientific studies, Multi and Hyperspectral system are now becoming readably available in off the shelf products at affordable prices. Appropriately used this allows vision systems to identify different materials, contents and contamination within live production processes.

Human sight is a general combination of red, blue and green types of light energy that are perceived as colour. Multispectral imaging extends this perception to include additional types of light energy as an overall more comprehensive image. Hyperspectral is true next level and expand this perception into hundreds of very precise types of light energy.

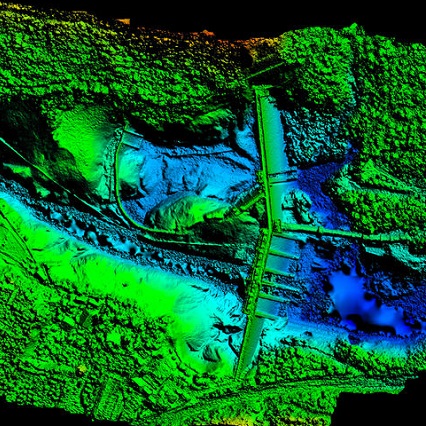

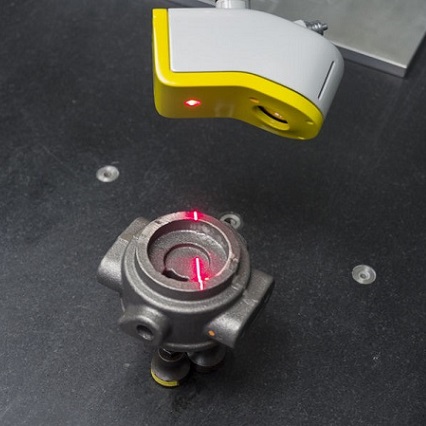

3D Imaging Systems

Give systems the means to accurately measure and track objects with reliable and easy to integrate devices. Often overlooked, 3D imaging systems can also provide simple solutions to non 3D problems due to the building blocks that form the technology.

The team at Edge Robotics & Automation has experience with various forms of 3D vision technology including customisable systems for unique challenges.

Robotic Vision Integration

Provide robots a means of sight to adapt for production variability or perform online quality control.

Various forms of robot vision exist using 2D or 3D cameras and either mounted on robot tools or in fixed locations; all covered by Edge Robotics & Automations past experience.

The flexibility provided by vision systems can also remove the need for complex mechanical fixtures providing numerous benefits. such as increased reliability by reduced the count of moving parts and offer Industry 4.0 capability for automatic process changes.

Optics & Lighting

A secret to mastering machine vision systems is an expert understanding of how to attain the best image for the software to work its magic.

A correctly designed vision system will contrast the features of interest in a clear and consistent manner while hiding irrelevant detail. Correctly designing the lighting and optical design of a vision system is a key component to reduce the complexity, and therefore cost of the software solution.

In addition to simpler challenges of discrete lighting, Edge Robotics and Automation has experience undertaking functions such as dynamically changing lighting conditions to suit multiple camera, developing special coatings, and precision optics for inspecting to 0.005 mm.