Industry 4.0 Overview

Industry 4.0 is essence a concept built around machine connectivity and shared intelligence much like the internet has forever changed global commerce and communities. As the internet has changed the world of commerce, Industry 4.0 is the next leap by greatly improving efficiency and the opportunity for mass customisation within the industrial sector.

How Industry 4.0 Works

Industry 4.0 (I4.0) is enabled by a range of new technologies and changing how industrial systems are designed. Information and feedback from the factory becomes a key factor, this provides real-time actionable information to react in the short term and quantifiable metrics to drive process improvement. These intelligent I4.0 systems then use this analysis, new machine connections and business planning systems to adjust the physical machines around the factory in real-time.

Key Industry 4.0 Technology

(Industrial) Internet of Things – (I)IoT

The Internet of Things is the concept to inter-connect all “things” such as sensors, machines, robots as the internet has already done for the PC.

Specifically related to the Industrial Internet of Things, the engineering models move from isolated machine “islands” to one big digital system across an entire company or the wider globe.

IIot by itself provides little value, however, it is this extensive machine communication and information capturing that enables wider I4.0 technologies and resultant benefits.

Edge Robotics and Automation has experience connecting sensors and machines across common networks or cloud services.

Big Data and Data Analytics

Big Data and Data Analytics is how to gather the massive amount of IIoT data, make sense of that data, then feedback the results in real-time to the physical systems and draw conclusions for company operations. Used correctly Big Data and Data Analytics offers extensive transparency of all factory operations, provides a means real-time or even preemptive corrective action, and helps guide decision making at all levels of management.

Edge Robotics and Automation has experience with data processing, optimisation and machine learning across a range of challenges.

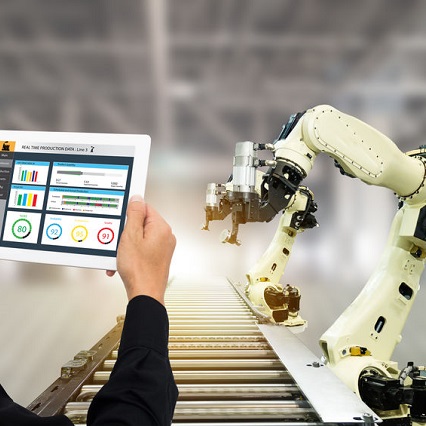

Cyber-Physical Systems

Cyber-Physical systems pass the control of the physical machines to the data analytics and cloud IT systems. This remote data driven control is what realises many of the benefits from Industry 4.0 technology. Real-time tuning and corrective action from data analytics has a means to automatically make changes without humans slowing down the process. Business systems have the ability to directly tie machines to planning systems and achieve a better synergy across the entire operation.

Edge Robotics and Automation has experience connecting machines to Manufacturing Execution Systems (MES) and Cloud Services