Robotic Experience

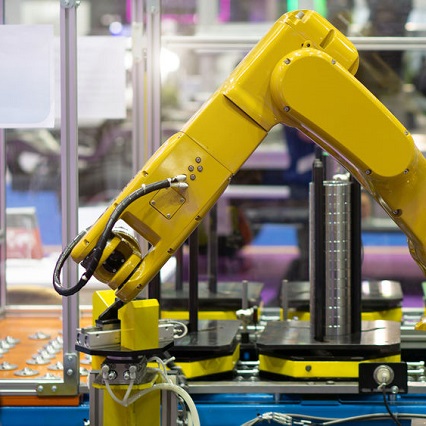

Edge Robotics and Automation has experience that covers the majority of “The Big 5” world leading industrial robot manufacturers.

Our range of robot experience has covered small high-speed robots moving faster than the human eye, to large behemoths capable of moving loads exceeding 300kg.

Robot Manufactures

We believe keeping to the big manufactures is the correct long term strategy for our local industry; even if that potentially hurts our own interests.

The big manufacturers often have factory service and part support bases within oceania or nearby, significantly larger R&D budgets for on going development, and a wide coordinated product map of robot models and accessories.

Specialist Robotic Skills

Our applications experience goes beyond the ordinary pick ‘n’ place or palletiser type systems and has included integrating many advanced robotic functions.

Robotic 2D & 3D Vision Systems

Provide robots sight as a means of adapting for production variability or performing online quality control.

Multi Robot Synchronisation

Allow more complex process, smaller footprints, and higher production rates.

Robotic Industry 4.0 Applications

Take advantage of inherent intelligence and flexibility of robotic automation.

Gentle and Touch Control Sensing

Give robots the ability to handle workpieces with the care or precision of a human hand or even beyond.

Advanced Robot Safety

Advanced robot safety allows the continuous human interaction as part of the production process.

System & Sensor Sychronisation

Robotic Articles

Robotic Vision Systems

Provide robots sight as a means of adapting for production variability or performing online quality control.

Various forms of robot vision exist using 2D or 3D cameras, and either mounted in fixed locations on robot tools; all covered by Edge Robotics & Automations past experience.

The flexibility provided by vision systems can provide numerous others benefits such as removing the need for complex mechanical fixtures. This for example can offer increased reliability by reducing moving parts or enabling Industry 4.0 capability for automatic process changes.

Gentle Robotic Handling and Touch Control

Give robots the ability to handle workpieces with the care or precision of a human hand or even beyond. Typical robotic systems are rigid in movement and do not adapt to tolerances or other variations.

Edge Robotics & Automation has the experience with the special sensing and software tools to give even the big behemoth robots a delicate hand.

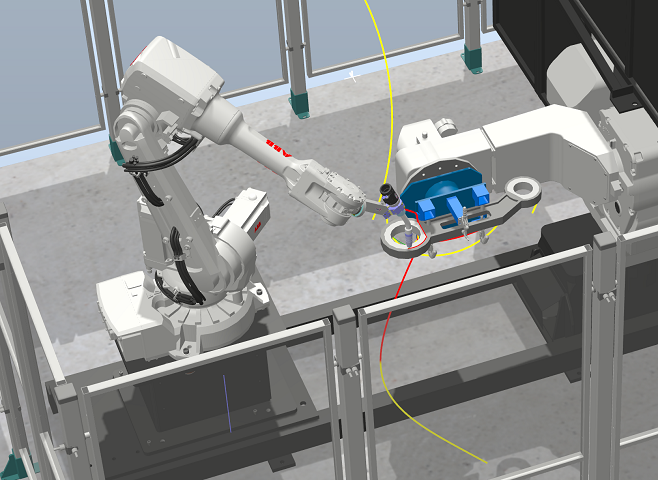

Multi-Robot Synchronisation

Coordinating or synchronizing multiple robots can take your system to the next level. This allows the implementation of more complex process, smaller footprints, and higher production rates.

Edge Robotics and Automation have experience with multi-robot systems and have integrated advanced tools and programming methods to avoid robot collisions and synchronise inter-robot motion.

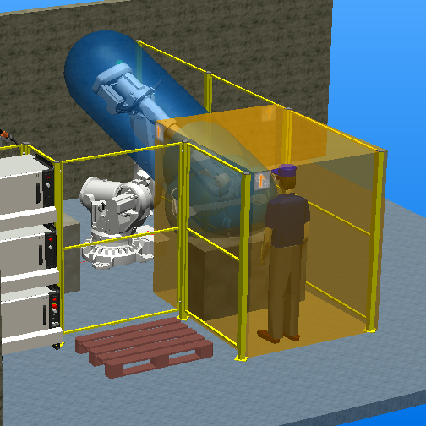

Advanced Robotic Safety

Robotic systems can be extremely hazardous machines with inherent high speed and power, combined with unexpected behaviour that catch personnel off guard.

Advanced robot safety allows the continuous human interaction as part of the production process. This offers opportunities to greatly improve the efficiency of conventional robotic applications and opens completely new applications to robotic automation

Edge Robotics and Automation has experience with cobots and advanced safety functions on industrial robots that provide cobot functionality even for the large behemoths models.

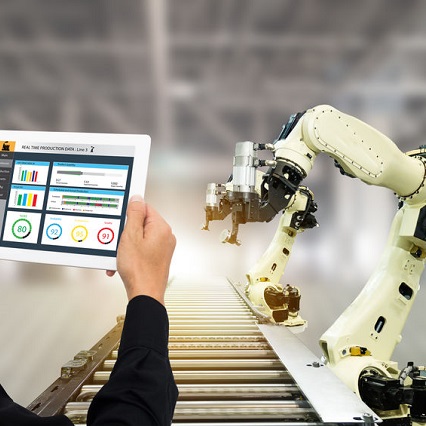

Robotic Industry 4.0 Applications

Take advantage of inherent intelligence and flexibility of robotic automation. Robots are well suited to handling customisable and small batch production orders by communicating with production ordering systems and adapting on the fly to suit.

Edge Robotics and Automation has a range of experience integrating robotic automation with various forms of databases, manufacturing execution systems (MES) and reporting.

Sensor & System Synchronisation

Robotic based sensing

Using robot mounted sensors or other tools to allow new means of intelligent measurement, quality control and efficiency gains.

External motion

Locate robots on movable gantry structures to increase reachability or synchronisation robot motion with conveyors, servo axes or other mechanisms.

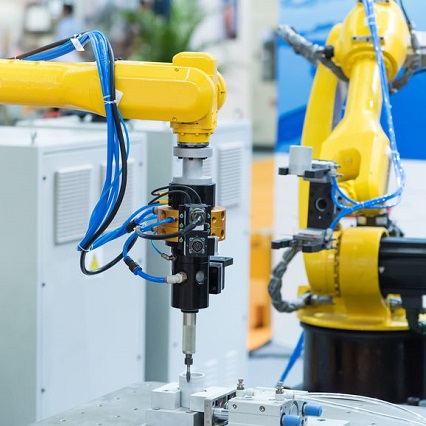

Robotic Grippers & Tooling

A key ingredient to industrial robotics is the design of the grippers or tooling. Industrial robot manufacturers provide mass produced off the shelf robotic systems and are ready to go except for what is formally known as End Of Arm Tooling(EOAT) and the integration to the wider system.

Tooling options are limitless with all manner of devices and configurations that can be mounted to suit different applications. Due to the wide range of robot applications tooling is typically a full custom design, or adapted for each particular system.

Edge Robotics and Automation has experience designing a range of different tools and our

industrial research background further includes advanced robotic grasp intelligence to optimise both speed and delicate handling.

Grippers

Numerous means of grasping and controlling loads can be built into a robotic tool. Simple vacuum cup or pneumatic cylinder based designs are common in many systems. Precision Servo grippers are another option for precision handling and high speeds.

Multi-Head or Purpose Tools

Increase production rates by using multiple grippers on one tool or a single integrated unit to accomplish a range of tasks

Tool Changers

Automatically change tools within complex production process or handle automatic SKU changes for Industry 4.0

Vision and Sensing

Add sight and sensing to robot tooling allowing adaptability to various objects and flexibility to operate with fixed tooling